Register now or log in to join your professional community.

If the voltage is reaching the circuit board, then look for the fuse and see if it is blown, if the fuse is okay check also the surge limiter is open or not.If these two components are okay then most likely there is no short on the primary side of the power supply.Note:Short in the primary side of the power supply usually cause the surge limiter or the fuse to blow.From now on we shall be using the main capacitor negative as the Ground for all the measurements of the voltages on the primary side of the power supply.I have modified my meter ground probe with a crocodile clip so that I can attach it to the ground point of the equipment I am repairing and therefore I use only one hand to probe the circuit.This is safety precaution because as you know for there to have a potential difference there must be a connection between the live and the ground.So if you are using your two hands and incidentally touch the live and the ground then the current will flow through your body and this can be fatal. But if you are using one hand it is not possible.

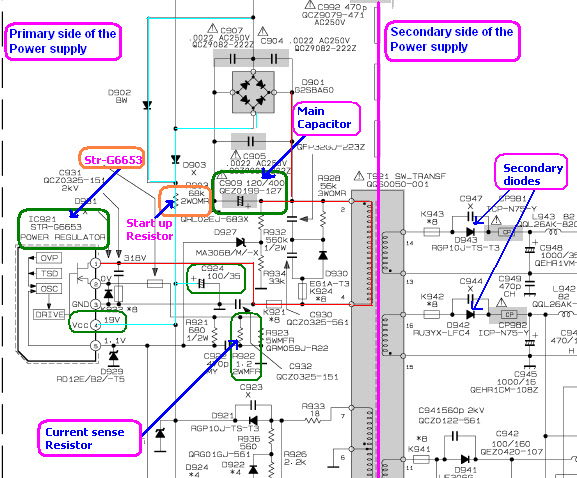

If the voltage is reaching the circuit board, then look for the fuse and see if it is blown, if the fuse is okay check also the surge limiter is open or not.If these two components are okay then most likely there is no short on the primary side of the power supply.Note:Short in the primary side of the power supply usually cause the surge limiter or the fuse to blow.From now on we shall be using the main capacitor negative as the Ground for all the measurements of the voltages on the primary side of the power supply.I have modified my meter ground probe with a crocodile clip so that I can attach it to the ground point of the equipment I am repairing and therefore I use only one hand to probe the circuit.This is safety precaution because as you know for there to have a potential difference there must be a connection between the live and the ground.So if you are using your two hands and incidentally touch the live and the ground then the current will flow through your body and this can be fatal. But if you are using one hand it is not possible. One thing I have learn in electronics is that if you master doing your troubleshooting using voltage tests you will have an added advantage because in electronics it is not always the component that fail but it could be just a crack on the circuit board that is preventing the voltage to flow or even dry joints and therefore if you concentrate on looking for the bad component you are going to waste a lot of time and end up not repairing the set.Therefore I encourage you to narrow down to the faulty circuit (area) by using voltage testing only. This one is very fast and valuable method I have come to learn.Now set your meter to DC range of1000VDC and use the main capacitor as your ground.First check the voltage across this main capacitor and if you get around300 vdc on220vac outlet or150 vdc on110 vac outlet then it is assumed the supply is okay up to the main capacitor.If there is no voltage at the main capacitor then check backward looking for open component or circuit board cracked or dry joint on the power path.

One thing I have learn in electronics is that if you master doing your troubleshooting using voltage tests you will have an added advantage because in electronics it is not always the component that fail but it could be just a crack on the circuit board that is preventing the voltage to flow or even dry joints and therefore if you concentrate on looking for the bad component you are going to waste a lot of time and end up not repairing the set.Therefore I encourage you to narrow down to the faulty circuit (area) by using voltage testing only. This one is very fast and valuable method I have come to learn.Now set your meter to DC range of1000VDC and use the main capacitor as your ground.First check the voltage across this main capacitor and if you get around300 vdc on220vac outlet or150 vdc on110 vac outlet then it is assumed the supply is okay up to the main capacitor.If there is no voltage at the main capacitor then check backward looking for open component or circuit board cracked or dry joint on the power path.

Be sure this main DC(300vdc or150vdc) is reaching the power regulator ic collector/drain pin, Now still using the same ground move the positive probe and measure the vcc-IN pin of the power regulator ic.

Be sure this main DC(300vdc or150vdc) is reaching the power regulator ic collector/drain pin, Now still using the same ground move the positive probe and measure the vcc-IN pin of the power regulator ic. Depending on the regulator used you can check the correct vcc-IN Supply (start up Voltage) from the data sheet for the ic used from the internet.These two voltages are very important and if any is missing the supply will appear dead, if the vcc-IN is missing this means there is a open circuit or start up resistor is open.Follow backward and find what is preventing the start up voltage from reaching the vcc-IN pin.Another hint: if you see this vcc is less than normal and pulsating there is a possibility that there is a short on that pin, to confirm just lift up that pin and if the voltage increases then it means there is a short on that pin internally and the ic must be replaced.There is also a filter capacitor for this source usually100uF/35V, please check the ESR of this capacitor or directly replace it if you don’t have an ESR meter.There is also a resistor linked to the source pin of this ic called the current sense resistor which sometimes open or change value and this can cause the power supply not to start. Usually it is a very low ohm resistor, less than2 ohms and around2 watts so it is a big one.If up to here you have checked and everything is okay, then you should suspect a short on the secondary side of the s.m.p.s.First measure for short of any of the secondary diode using analogue meter set to X1, when you measure across any diode on the secondary you should not have two reading and if you get two reading lift up one leg and test again. If you still get two reading then you can conclude that diode is shorted.Also when using this method and find that the diode has two reading in-circuit and when lifted up you get one reading, it could also mean there is a short on that source (line).You can follow that source looking for the shorted component; usually the most common components to short are transistors, ics, diodes, capacitors.Remember when doing voltage testing on the secondary circuit you should be using the COLD GROUND of the set.The best cold ground to use is the turner ground (out part) or the CRT ground return.

Depending on the regulator used you can check the correct vcc-IN Supply (start up Voltage) from the data sheet for the ic used from the internet.These two voltages are very important and if any is missing the supply will appear dead, if the vcc-IN is missing this means there is a open circuit or start up resistor is open.Follow backward and find what is preventing the start up voltage from reaching the vcc-IN pin.Another hint: if you see this vcc is less than normal and pulsating there is a possibility that there is a short on that pin, to confirm just lift up that pin and if the voltage increases then it means there is a short on that pin internally and the ic must be replaced.There is also a filter capacitor for this source usually100uF/35V, please check the ESR of this capacitor or directly replace it if you don’t have an ESR meter.There is also a resistor linked to the source pin of this ic called the current sense resistor which sometimes open or change value and this can cause the power supply not to start. Usually it is a very low ohm resistor, less than2 ohms and around2 watts so it is a big one.If up to here you have checked and everything is okay, then you should suspect a short on the secondary side of the s.m.p.s.First measure for short of any of the secondary diode using analogue meter set to X1, when you measure across any diode on the secondary you should not have two reading and if you get two reading lift up one leg and test again. If you still get two reading then you can conclude that diode is shorted.Also when using this method and find that the diode has two reading in-circuit and when lifted up you get one reading, it could also mean there is a short on that source (line).You can follow that source looking for the shorted component; usually the most common components to short are transistors, ics, diodes, capacitors.Remember when doing voltage testing on the secondary circuit you should be using the COLD GROUND of the set.The best cold ground to use is the turner ground (out part) or the CRT ground return. Now identify the main supply to the fly back called the B+ and disconnect the supply just before the fly back B+ vcc pin. Don’t cut the circuit board to do this just lift up one side of a resistor( high wattage) in series with this B+ voltage or sometime they use a jumper wire just before the B+ vcc pin of the fly back and attach your dummy load between this point and the cold ground.If the bulb light steadily and you measure between90 Volts dc to140 dc depending on the size of the television then you can assume that the s.m.p.s is okay and the problem is on the secondary side.In conclusion let me say that any technician who is smart at troubleshooting power supplies (both linear and s.m.p.s) will definitely have an edge in repairing all types of equipments because this is the main cause of many electronics problems.Here is another version of solving S.M.P.S. using flow chart by Beh, a renowned technician from Iran

Now identify the main supply to the fly back called the B+ and disconnect the supply just before the fly back B+ vcc pin. Don’t cut the circuit board to do this just lift up one side of a resistor( high wattage) in series with this B+ voltage or sometime they use a jumper wire just before the B+ vcc pin of the fly back and attach your dummy load between this point and the cold ground.If the bulb light steadily and you measure between90 Volts dc to140 dc depending on the size of the television then you can assume that the s.m.p.s is okay and the problem is on the secondary side.In conclusion let me say that any technician who is smart at troubleshooting power supplies (both linear and s.m.p.s) will definitely have an edge in repairing all types of equipments because this is the main cause of many electronics problems.Here is another version of solving S.M.P.S. using flow chart by Beh, a renowned technician from Iran

Very often when I attempt to repair electronic devices, either mine or from friends, I find out the problem is with the power supply which these days is most often a Switched Mode Power Supply (SMPS). Most of them are flyback, regulated, SMPS (but not all!). In this post I will be discussing the repair of flyback SMPS and a basic understanding of how flyback power supplies work is assumed. In my experience, most of the time the output electrolytic capacitors failed and if you are lucky this is all that needs to be replaced but sometimes this has lead to other components also failing. Electrolytic output capacitors fail a lot and SMPS designers need to catch up with this problem. These capacitors are being subjected to high currents of high frequency and are stressed beyond their designed capabilities. Not to mention that there are cheap, bad quality, caps being used out there. This has lead to the so-called capacitor plague. A very useful tool in checking and diagnosing electrolytic capacitors is an ESR meter. This tool allows for a quick check of all electrolytic capacitors without removing them from the circuit. I built myself an ESR meter based on this article which is itself a practical building of a design published by the Italian magazine Nuova Elettronica N212 as kit1518. I made some modifications (which I think are improvements) to that design and the device has been very useful to me in repairing power supplies. An ESR meter does not measure capacitance but ESR (duh!) which is a very good indication of a capacitor's health and well-being. I recommend this tool and understanding how it works to anyone who will be repairing power supplies. Besides this one there are plenty of designs out there which can be easily and cheaply built by the amateur. One thing I like about this one is that it signals if the cap is shorted. This is very important because a shorted cap looks ideal with regards to ESR. The building of such an ESR meter would be a worthwhile project for anyone who does not own one. So, when confronted with a non-working SMPS the first step is checking all output capacitors and replacing any defective ones. Replace them with good quality, low ESR capacitors. As the hobbyist may not have access to high quality capacitors ad, especially, to ESR information, my advice is to generally use higher capacity than originally installed which means lower ESR and the cap generally being less stressed. Bigger capacitors will have smaller ESR than smaller capacitors. Two1000 uF caps in parallel will have lower ESR than one2000 uF cap. The (generally schottky) output diodes should also be checked and replaced if necessary. Up to here it is all very straightforward. At this point, if we are very lucky, the SMPS might work again but it may be that other components were damaged. The first one to look for is the switching element on the primary side of the transformer. Here things can start getting tricky because it will be mounted on a heat sink, it may be difficult or impossible to find a replacement, etc. Other components, including the control IC may be damaged as well. Sometimes the switching element and the control circuit are on the same IC like the STRT-G6153. If the switching element shorted then the fuse blew and maybe the diodes of the rectifier bridge also blew. These elements are easy to check and replace if necessary. If the switching transistor and/or bridge diodes were blown it makes sense to insert a lightbulb in series with the mains when testing because that limits the current and the damage should anything else still be wrong. I remember in my first attempts to repair blowing one transistor after another... So sometimes we get to the point where we have checked the output side and the input rectifier bridge and capacitor but the SMPS is still not working due to the switching element and/or other feedback/control parts. Now things can get tricky. We can test all components individually one by one but this can get tiring and may not be possible with all components. Many would have to be removed from the circuit. And the problem is that there is no way to test parts of the power supply because it need the feedback of the regulation. if something, anything, is not working, then with no feedback the power supply will just blow. So I am considering building a tool which would have certain parts of a power supply and which could be connected to a power supply under test. This tool would provide some of the functions like the feedback and the switching element so that it could temporarily replace those parts of the SMPS being repaired. Maybe even provide manually adjustable duty cycle switching. The idea is to provide external, protected, DC voltage to the primary side and a switching element which can be adjusted in duty cycle (I can see a555 coming). Plus a load on the secondary side. The idea is something like this: with voltage on the primary and load on the output side we slowly start switching pulses which start from zero duty cycle very slowly up and see if power is being transferred to the load. Feedback could be used to adjust the duty cycle. An isolation transformer would isolate from the mains and a lightbulb in series would limit the current (and the damage). This tool would be designed for SMPS which have mains voltage input and low voltage output (say anywhere between5 to25) which seems to cover most cases. I am working on this idea which is intended to be extremely simple and, hopefully, useful. All comments are welcome.

Do you need help in adding the right keywords to your CV? Let our CV writing experts help you.